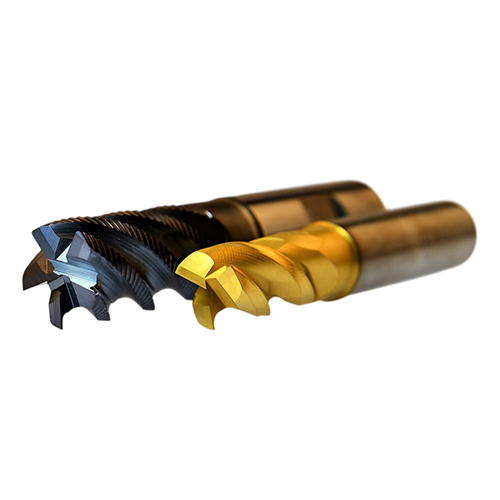

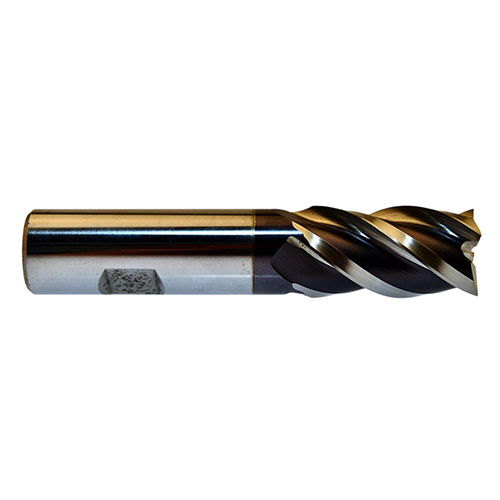

Solid Carbide Rougher End Mill

Price 3000.0 INR/ Dozen

MOQ : 10 Dozens

Solid Carbide Rougher End Mill Specification

- Shape

- Various Available

- Hardness

- Hard

- Coating

- Polished

- Usage

- Industrial

- Material

- Tungsten Carbide

- Features

- High Quality

Solid Carbide Rougher End Mill Trade Information

- Minimum Order Quantity

- 10 Dozens

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Dozens Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Solid Carbide Rougher End Mill

Experience the superb machining performance of our Solid Carbide Rougher and End Mill, now available at marked-down rates for a limited sale. Meticulously crafted from resplendent tungsten carbide, these industrial tools offer superior hardness and polished coatings for extended lifespan. With various shapes to suit diverse applications, our products guarantee remarkable versatility and high-quality results. Reserve yours today from a leading manufacturer, supplier, and trader in India. Harness precision, reliability, and extraordinary durability for all your heavy-duty cutting needs.

Competitive Advantages & Industrial Applications

Our Solid Carbide Rougher and End Mill boasts superior toughness and longevity, making it indispensable across diverse industrial sectors. Its high-quality build and robust polished coating provide optimal resistance against abrasive wear, ensuring consistent performance. These tools find extensive commercial use in metalworking plants, automotive manufacturing, aerospace component fabrication, and general engineering applications, making them a top choice for maximizing productivity and reliability.

Sample, Packaging & Supply for Export Market

Sample pieces of our Solid Carbide Rougher and End Mill are readily available, enabling customers to evaluate quality before a larger order. We ensure secure packaging for safe transit and timely delivery of shipped goods, accommodating bulk and varied-volume requirements. Our superior supply ability ensures competitive rate quotes and seamless order fulfillment, making us an ideal partner for clients targeting the export market and demanding frequent, efficient logistics.

Competitive Advantages & Industrial Applications

Our Solid Carbide Rougher and End Mill boasts superior toughness and longevity, making it indispensable across diverse industrial sectors. Its high-quality build and robust polished coating provide optimal resistance against abrasive wear, ensuring consistent performance. These tools find extensive commercial use in metalworking plants, automotive manufacturing, aerospace component fabrication, and general engineering applications, making them a top choice for maximizing productivity and reliability.

Sample, Packaging & Supply for Export Market

Sample pieces of our Solid Carbide Rougher and End Mill are readily available, enabling customers to evaluate quality before a larger order. We ensure secure packaging for safe transit and timely delivery of shipped goods, accommodating bulk and varied-volume requirements. Our superior supply ability ensures competitive rate quotes and seamless order fulfillment, making us an ideal partner for clients targeting the export market and demanding frequent, efficient logistics.

FAQ's of Solid Carbide Rougher And End Mill:

Q: How does the solid carbide construction benefit industrial usage?

A: The solid carbide construction enhances hardness, toughness, and heat resistance, resulting in prolonged tool life and superior cutting performance under demanding industrial conditions.Q: What materials are best suited for machining with these roughers and end mills?

A: These tools are engineered for excellence in machining steel, cast iron, non-ferrous metals, and hard alloys, handling tough materials without compromising quality or precision.Q: When should I choose a rougher versus an end mill?

A: Use roughers for rapid material removal in the initial stages of machining, while end mills are ideal for finishing operations requiring precision and finer tolerances.Q: Where are these solid carbide tools most commonly applied?

A: They are widely applied in automotive, aerospace, shipbuilding, and general metalworking industries, particularly within cutting, milling, and finishing plants.Q: What is the process for reserving a sample or placing a bulk order?

A: Simply contact our sales team with your requirements. We provide sample pieces for initial assessment and offer flexible bulk order options to suit your operational needs.Q: How does the polished coating enhance the tool's performance?

A: The polished coating reduces friction, improves chip evacuation, and prolongs tool life, ensuring superior surface finishes and consistent output.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Solid Carbide Cutting Tools Category

Solid Carbide Drills

Price 1500.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Hardness : Hard

Shape : Various Available

Features : High Quality

Material : Tungsten Carbide

Solid Carbide Twist Drill

Price 3000.0 INR / Piece

Minimum Order Quantity : 7 Pieces

Hardness : Hard

Shape : Various Available

Features : High Quality

Material : Tungsten Carbide

Solid Carbide Micro tools from 0.003

Price 1500.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Hardness : Hard

Shape : Various Available

Features : High Quality

Material : Tungsten Carbide

Solid Carbide End Mills

Minimum Order Quantity : 100 Pieces

Hardness : Hard

Shape : Various Available

Features : High Quality

Material : Tungsten Carbide

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese