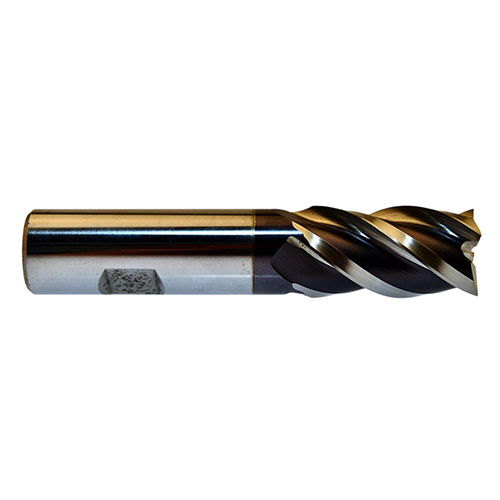

Solid Carbide End Mills

MOQ : 100 Pieces

Solid Carbide End Mills Specification

- Coating

- Polished

- Material

- Tungsten Carbide

- Features

- High Quality

- Shape

- Various Available

- Hardness

- Hard

- Usage

- Industrial

Solid Carbide End Mills Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Solid Carbide End Mills

Experience a Price Cut and exciting Discount on our superb Solid Carbide End Mills, crafted from unparalleled Tungsten Carbide for industrial excellence. Available in a variety of shapes and featuring a sterling polished coating, these end mills promise exceptional durability and consistent results. The hard material strength ensures long-lasting performance under rigorous demands, making them a preferred choice for manufacturers, suppliers, and traders across India. Enjoy fresh, high-quality tooling solutions designed to meet your toughest machining challenges and deliver sterling performance every cycle.

Unparalleled Features and Advantages of Solid Carbide End Mills

Engineered for high performance, our Solid Carbide End Mills feature robust hardness and a polished finish that ensures longevity. The advanced Tungsten Carbide material offers superb wear resistance and edge retention, reducing downtime and boosting operational efficiency. Precision-engineered for various industrial uses, these end mills deliver consistent, high-quality cuts while accommodating different machining requirements, giving you an edge in productivity and finish quality.

Hassle-Free Payment, Quick Delivery, and Streamlined Drop-Off

We offer transparent pricing with competitive proposal amounts for every order. Payment terms are customer-oriented and easy to arrange, making the charge process straightforward. Expect a reliable drop-off at your designated FOB port, with prompt delivery times tailored to your business schedules. Our coordinated supply chain guarantees a seamless experience from quotation to product arrival, ensuring you can meet critical timelines without compromise.

Unparalleled Features and Advantages of Solid Carbide End Mills

Engineered for high performance, our Solid Carbide End Mills feature robust hardness and a polished finish that ensures longevity. The advanced Tungsten Carbide material offers superb wear resistance and edge retention, reducing downtime and boosting operational efficiency. Precision-engineered for various industrial uses, these end mills deliver consistent, high-quality cuts while accommodating different machining requirements, giving you an edge in productivity and finish quality.

Hassle-Free Payment, Quick Delivery, and Streamlined Drop-Off

We offer transparent pricing with competitive proposal amounts for every order. Payment terms are customer-oriented and easy to arrange, making the charge process straightforward. Expect a reliable drop-off at your designated FOB port, with prompt delivery times tailored to your business schedules. Our coordinated supply chain guarantees a seamless experience from quotation to product arrival, ensuring you can meet critical timelines without compromise.

FAQ's of Solid Carbide End Mills:

Q: How do I select the right shape of Solid Carbide End Mill for my application?

A: Choosing the right shape depends on your machining needs. Consider the material to be cut, required finish, and specific operation to determine the most suitable geometry from our range of available shapes.Q: What are the benefits of using Tungsten Carbide material in end mills?

A: Tungsten Carbide end mills provide unparalleled durability, superb hardness, and excellent resistance to wear, making them ideal for demanding industrial applications and ensuring a longer tool life.Q: Where can these Solid Carbide End Mills be used?

A: These end mills are designed for industrial applications across various sectors, including manufacturing, metalworking, and precision engineering, where high-quality and reliable cutting tools are essential.Q: What is the process for ordering and receiving Solid Carbide End Mills?

A: Simply contact us with your requirements, and we will provide a proposal amount based on your specifications. Once confirmed, you will receive details on payment charges and anticipated drop-off or FOB port delivery timelines.Q: How does the polished coating enhance the performance of these end mills?

A: The polished coating helps reduce friction and prevent material build-up on the tool, resulting in smoother operation, superior finishes, and extended tool life during intensive machining tasks.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Solid Carbide Cutting Tools Category

Solid Carbide Rougher Endmill

Price 4500.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Coating : Polished

Material : Tungsten Carbide

Features : High Quality

Usage : Industrial

Solid Carbide Endmill

Price 1000.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Coating : Polished

Material : Tungsten Carbide

Features : High Quality

Usage : Industrial

Solid Carbide ID Grooving Tool

Price 600.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Coating : Polished

Material : Tungsten Carbide

Features : High Quality

Usage : Industrial

Solid Carbide Chamfer Tool

Price 700.0 INR / Number

Minimum Order Quantity : 10

Coating : Polished

Material : Tungsten Carbide

Features : High Quality

Usage : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese