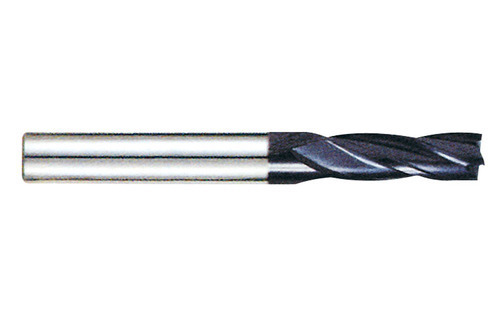

Solid Carbide Slitting Cutter

Price 4000.0 INR/ Piece

MOQ : 10 Pieces

Solid Carbide Slitting Cutter Specification

- Shape

- Various Available

- Usage

- Industrial

- Material

- Tungsten Carbide

- Features

- High Quality

- Hardness

- Hard

- Coating

- Polished

Solid Carbide Slitting Cutter Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Solid Carbide Slitting Cutter

Discover celebrated performance with our Solid Carbide Slitting Cutter, designed for those who value unmatched efficiency and longevity. Manufactured using premium tungsten carbide, these cutters deliver grand results across demanding industrial applications. Their polished coating ensures unprecedented hardness and wear resistance, while the diverse range of available shapes makes it easy to find the perfect fit. Widely popular among manufacturers, suppliers, and traders throughout India, stock is limited-so seize this high-quality, hard material solution for precise slitting needs before it's gone!

Solid Carbide Slitting Cutter: Versatile Industrial Applications

Solid Carbide Slitting Cutters are extensively used in industrial environments for precise cutting, parting, and grooving operations. They serve as critical tools for processes in manufacturing, aerospace, automotive, and electronics sectors. These cutters are also employed in shaping, slotting, and trimming hard materials where superior strength and durability are essential. Their high hardness and polished finish make them highly efficient, offering reliable performance in challenging settings and across multiple types of industrial machinery.

Supply Ability and Export Markets for Solid Carbide Slitting Cutters

Our supply ability ensures that Solid Carbide Slitting Cutters are dropped off at the client's location or handed over at FOB ports on time, maintaining a steady rate of availability. We regularly export to major markets in Asia, the Middle East, Africa, and Europe. Every batch shipped reflects our commitment to quality and timely delivery, allowing us to support clients' operational timelines with ease and reliability across various global destinations.

Solid Carbide Slitting Cutter: Versatile Industrial Applications

Solid Carbide Slitting Cutters are extensively used in industrial environments for precise cutting, parting, and grooving operations. They serve as critical tools for processes in manufacturing, aerospace, automotive, and electronics sectors. These cutters are also employed in shaping, slotting, and trimming hard materials where superior strength and durability are essential. Their high hardness and polished finish make them highly efficient, offering reliable performance in challenging settings and across multiple types of industrial machinery.

Supply Ability and Export Markets for Solid Carbide Slitting Cutters

Our supply ability ensures that Solid Carbide Slitting Cutters are dropped off at the client's location or handed over at FOB ports on time, maintaining a steady rate of availability. We regularly export to major markets in Asia, the Middle East, Africa, and Europe. Every batch shipped reflects our commitment to quality and timely delivery, allowing us to support clients' operational timelines with ease and reliability across various global destinations.

FAQ's of Solid Carbide Slitting Cutter:

Q: How can I use a Solid Carbide Slitting Cutter efficiently?

A: To utilize a Solid Carbide Slitting Cutter efficiently, ensure it is installed securely in your industrial machinery, select the correct shape for your application, and operate at the manufacturer's recommended speeds for optimal cutting and reduced wear.Q: What are the main benefits of choosing a tungsten carbide slitting cutter?

A: Tungsten carbide slitting cutters offer high hardness, exceptional durability, and resistance to wear, making them perfect for demanding industrial cutting tasks. Their superior edge retention leads to longer intervals between replacements and consistent results.Q: When should I select a coated and polished slitting cutter?

A: A coated and polished cutter is ideal when precision, longevity, and reduced friction are required in your job. These features are especially advantageous for high-speed operations and when cutting hard or abrasive materials.Q: Where are these slitting cutters manufactured and supplied from?

A: These Solid Carbide Slitting Cutters are manufactured, supplied, and traded by reliable companies based in India, servicing both domestic and international customers across multiple industries.Q: What is the process for ordering and receiving Solid Carbide Slitting Cutters?

A: You can place your order through authorized suppliers or manufacturers. The products are then carefully prepared and either dropped off at your location or handed over at designated FOB ports, ensuring a secure and efficient delivery.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Solid Carbide Cutting Tools Category

Solid Carbide End Mill for stainless steel

Price 3000.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Tungsten Carbide

Features : High Quality

Hardness : Hard

Coating : Polished

Solid Carbide ID Grooving Tool

Price 600.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Tungsten Carbide

Features : High Quality

Hardness : Hard

Coating : Polished

Through Coolant Solid Carbide Drills

Price 4000.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Tungsten Carbide

Features : High Quality

Hardness : Hard

Coating : Polished

Solid Carbide Drill

Minimum Order Quantity : 100 Pieces

Material : Tungsten Carbide

Features : High Quality

Hardness : Hard

Coating : Polished

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese