Solid Carbide Drill For Aluminum

Price 2700.0 INR/ Piece

MOQ : 10 Pieces

Solid Carbide Drill For Aluminum Specification

- Operate Method

- Manual

- Usage

- Industrial

- Coating

- Polished

- Hardness

- Hard

- Material

- Tungsten Carbide

- Features

- High Quality

- Size

- Various Sizes Available

- Color

- As Per Demand

Solid Carbide Drill For Aluminum Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Solid Carbide Drill For Aluminum

Highlighted by their matchless performance, our Carbide Combination Step Drills capitalise on advanced design principles to deliver excellent results in industrial settings. Manufactured using meritorious Tungsten Carbide, these drills offer superior hardness, corrosion resistance and durability. Select from a variety of sizes and colours to suit your specific requirements, as per demand. The highly polished coating ensures smooth operation and extended tool life. Manually operated, these tools are perfect for professional craftspeople and traders seeking dependability from a reputable Indian manufacturer, supplier, and trader.

Applications and Methods for Carbide Combination Step Drills

Carbide Combination Step Drills are engineered for manual operation, making them ideal for precise drilling tasks across multiple diameters with a single tool. Used predominantly in sheet metal, plastic, and thin-walled material fabrication, they shine in industries such as automotive, construction, and electrical. Their versatility is highlighted in their ability to streamline drilling, reducing the time and effort needed for frequent tool changes in technical environments.

Packaging, Delivery, and Market Reach for Step Drills

We emphasise secure and sturdy packaging to ensure product safety during Supply and transit. Delivery times are swift and reliable, subject to order processing and quantity. Customers benefit from clear communication on List price and prompt support throughout their purchasing experience. Our primary domestic market spans across India, meeting the diverse and demanding needs of both small-scale enterprises and large industrial clients efficiently.

Applications and Methods for Carbide Combination Step Drills

Carbide Combination Step Drills are engineered for manual operation, making them ideal for precise drilling tasks across multiple diameters with a single tool. Used predominantly in sheet metal, plastic, and thin-walled material fabrication, they shine in industries such as automotive, construction, and electrical. Their versatility is highlighted in their ability to streamline drilling, reducing the time and effort needed for frequent tool changes in technical environments.

Packaging, Delivery, and Market Reach for Step Drills

We emphasise secure and sturdy packaging to ensure product safety during Supply and transit. Delivery times are swift and reliable, subject to order processing and quantity. Customers benefit from clear communication on List price and prompt support throughout their purchasing experience. Our primary domestic market spans across India, meeting the diverse and demanding needs of both small-scale enterprises and large industrial clients efficiently.

FAQ's of Carbide Combination Step Drills:

Q: How are Carbide Combination Step Drills typically operated?

A: These step drills are manually operated, allowing users to maintain full control over drilling speed and depth for different material thicknesses.Q: What materials are Carbide Combination Step Drills best used for?

A: They are meritorious for drilling through sheet metal, plastics, and other thin-walled materials, thanks to the excellent hardness of tungsten carbide.Q: Where can these drills be most effectively applied?

A: They are best suited for industrial environments such as automotive manufacturing, electrical component fabrication, and construction sectors.Q: What is the benefit of the polished coating on the drills?

A: The polished coating provides a smooth surface, reduces friction and heat, and prolongs the life of the tool, ensuring matchless performance over time.Q: What sizes and colour options are available for selection?

A: A wide range of sizes and colour finishes are available to capitalise on varied client demands and industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Carbide Tools Category

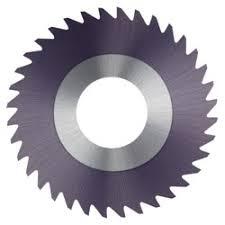

Carbide Slitting Saw Cutter

Price 3500.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Color : As Per Demand

Features : High Quality

Material : Tungsten Carbide

Hardness : Hard

Solid Carbide BallNose End Mill

Price 900.0 INR / Dozen

Minimum Order Quantity : 10 Dozens

Color : As Per Demand

Features : High Quality

Material : Tungsten Carbide

Hardness : Hard

Solid Carbide Step Drills

Price 2700.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Color : As Per Demand

Features : High Quality

Material : Tungsten Carbide

Hardness : Hard

Spiral Flute Solid Carbide Reamers

Price 4500.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Color : As Per Demand

Features : High Quality

Material : Tungsten Carbide

Hardness : Hard

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese