Regrinding Services for carbide tools

Price 300.0 INR/ Piece

MOQ : 100 Pieces

Regrinding Services for carbide tools Specification

- Hardness

- Hard

- Coating

- Polished

- Usage

- Industrial

- Material

- Tungsten Carbide

- Shape

- Various Available

- Features

- High Quality

Regrinding Services for carbide tools Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Regrinding Services for carbide tools

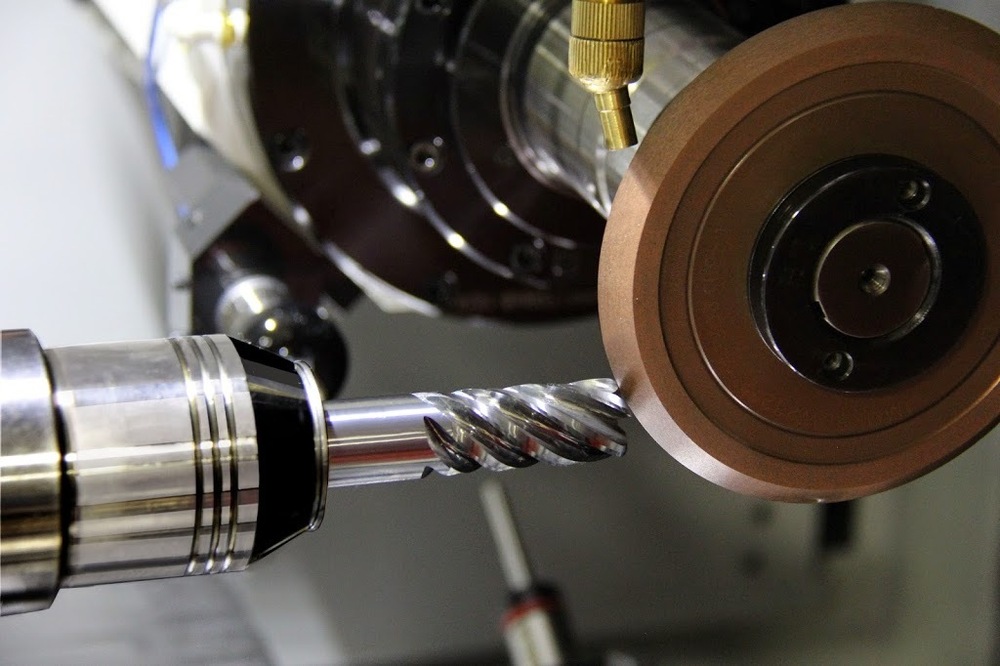

Experience the laureate of industrial tooling with our Solid Carbide Regrinding services, crafted using redoubtable Tungsten Carbide materials. As a top manufacturer, supplier, and trader in India, we offer a masterpiece of performance, ensuring unmatched hardness and adaptability across various shapes. Enjoy featured benefits like a polished coating and high-quality assurance, all at the best price. Our advance purchase options guarantee cost savings, while our commitment to excellence solidifies our place as a preferred choice in the industrial sector.

Diverse Industrial Utility & Competitive Advantages

Solid Carbide Regrinding is extensively employed across sectors such as automotive, aerospace, and heavy machinery, prized for its durability and adaptability. Esteemed manufacturers and industry leaders utilize this masterpiece for extending tool lifespan and enhancing productivity. Competitive advantages include a significant reduction in tooling costs and superior precision. High material hardness guarantees resilience, making it a redoubtable solution for demanding operations.

Efficient Delivery and Economical Packaging Solutions

Our Solid Carbide Regrinding is meticulously packed & dispatched from leading Indian FOB ports, ensuring quick and reliable delivery. Each consignment is securely packaged to preserve tool quality during transit. Orders are delivered promptly, and our lowest price commitment offers true value. We pride ourselves on efficient logistics and professional service at each delivery step, ensuring your order arrives ready for immediate industrial application.

Diverse Industrial Utility & Competitive Advantages

Solid Carbide Regrinding is extensively employed across sectors such as automotive, aerospace, and heavy machinery, prized for its durability and adaptability. Esteemed manufacturers and industry leaders utilize this masterpiece for extending tool lifespan and enhancing productivity. Competitive advantages include a significant reduction in tooling costs and superior precision. High material hardness guarantees resilience, making it a redoubtable solution for demanding operations.

Efficient Delivery and Economical Packaging Solutions

Our Solid Carbide Regrinding is meticulously packed & dispatched from leading Indian FOB ports, ensuring quick and reliable delivery. Each consignment is securely packaged to preserve tool quality during transit. Orders are delivered promptly, and our lowest price commitment offers true value. We pride ourselves on efficient logistics and professional service at each delivery step, ensuring your order arrives ready for immediate industrial application.

FAQ's of Solid Carbide Regrinding:

Q: How is the regrinding process for solid carbide tools executed?

A: The regrinding process involves precisely sharpening worn carbide tools using advanced equipment to restore their cutting performance. High-quality standards ensure consistent results and extended tool lifespan.Q: What benefits does solid carbide regrinding offer for industrial users?

A: Regrinding solid carbide tools significantly lowers replacement costs, improves cutting efficiency, and extends tool life, providing a sustainable and economically advantageous solution for industrial applications.Q: When should carbide tools undergo regrinding?

A: Carbide tools should be re-ground when there is visible wear or reduced cutting performance. Timely regrinding helps maintain productivity and avoids premature tool replacement.Q: Where are solid carbide regrinding services typically utilized?

A: These services are widely used by industries such as automotive, aerospace, machinery manufacturing, and metalworking, where tool performance and longevity are essential.Q: What are the packaging details and delivery timelines for orders?

A: Solid Carbide Regrinding orders are carefully packed to maintain condition and delivered from Indian FOB ports. Delivery timelines vary based on location but are optimized for prompt arrival.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Solid Carbide Cutting Tools Category

Solid Carbide combination tools

Price 2500.0 INR / Unit

Minimum Order Quantity : 10 Units

Usage : Industrial

Material : Tungsten Carbide

Features : High Quality

Shape : Various Available

Solid Carbide Endmill

Price 1000.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage : Industrial

Material : Tungsten Carbide

Features : High Quality

Shape : Various Available

Solid Carbide Drills

Price 1500.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Usage : Industrial

Material : Tungsten Carbide

Features : High Quality

Shape : Various Available

Solid Carbide Woodruff Cutter

Minimum Order Quantity : 100 Pieces

Usage : Industrial

Material : Tungsten Carbide

Features : High Quality

Shape : Various Available

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese