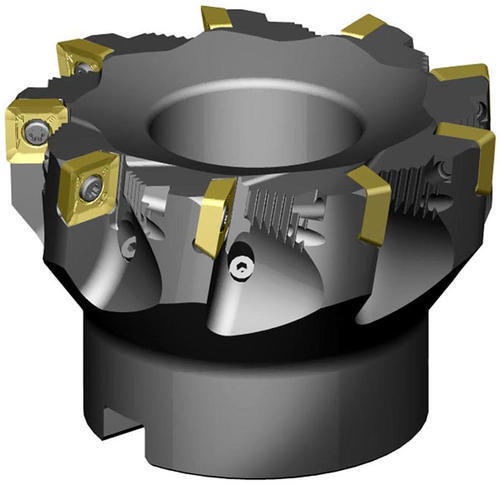

Deep Shoulder Milling Cutter

Price 7000.0 INR/ Piece

MOQ : 10 Pieces

Deep Shoulder Milling Cutter Specification

- Operate Method

- Manual

- Usage

- Industrial

- Features

- High Quality

- Hardness

- Hard

- Coating

- Polished

- Material

- Tungsten Carbide

- Size

- Various Sizes Available

Deep Shoulder Milling Cutter Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Deep Shoulder Milling Cutter

Procure the noble Deep Shoulder Milling Cutter, meticulously crafted from famed tungsten carbide for hard-wearing performance and sterling efficiency. Available in various sizes and sporting a polished coating, this cutter promises instant savings without compromising on quality. Its manual operation ensures precision and adaptability in industrial settings. As a trusted manufacturer, supplier, and trader in India, we empower professionals to achieve flawless finishing and deep cuts. Grab yours today to elevate your productivity with this high-quality, enduring tool, built for heavy-duty use.

Precision Usage of the Deep Shoulder Milling Cutter

The Deep Shoulder Milling Cutter is engineered for intensive industrial use, with manual operation tailored for machinists and engineers. This tool excels in heavy-duty side milling and deep slotting, making it ideal for creating accurate shoulders and grooves on metalwork. Its polished finish and robust tungsten carbide construction support seamless usage in manufacturing environments, ensuring efficient chip removal and extended tool life during high-speed operations.

Trustworthy Delivery and Packaging Details

Count on us for swift delivery and reliable dispatching of your Deep Shoulder Milling Cutter. Carefully packaged to prevent damage, each tool reaches you in pristine condition. Our list price includes attention to packaging standards suitable for the main domestic market across India, ensuring regional and national demands are met promptly. Expect your order to be handled with precision and timely dispatch from our facilities, with customer satisfaction as our top priority.

Precision Usage of the Deep Shoulder Milling Cutter

The Deep Shoulder Milling Cutter is engineered for intensive industrial use, with manual operation tailored for machinists and engineers. This tool excels in heavy-duty side milling and deep slotting, making it ideal for creating accurate shoulders and grooves on metalwork. Its polished finish and robust tungsten carbide construction support seamless usage in manufacturing environments, ensuring efficient chip removal and extended tool life during high-speed operations.

Trustworthy Delivery and Packaging Details

Count on us for swift delivery and reliable dispatching of your Deep Shoulder Milling Cutter. Carefully packaged to prevent damage, each tool reaches you in pristine condition. Our list price includes attention to packaging standards suitable for the main domestic market across India, ensuring regional and national demands are met promptly. Expect your order to be handled with precision and timely dispatch from our facilities, with customer satisfaction as our top priority.

FAQ's of Deep Shoulder Milling Cutter:

Q: How can I select the appropriate size of Deep Shoulder Milling Cutter for my needs?

A: Selecting the correct size depends on your specific machining application, the material thickness, and the type of grooves or shoulders you intend to create. Consult our size chart or contact our technical team for personalized recommendations.Q: What makes tungsten carbide a preferred material for this milling cutter?

A: Tungsten carbide is celebrated for its hardness, strength, and wear resistance, making these cutters exceptionally durable and well-suited for heavy-duty industrial applications where precision and longevity are paramount.Q: When will my Deep Shoulder Milling Cutter be delivered after placing an order?

A: Delivery timelines typically depend on order volume and your location, but we prioritize dispatching all orders promptly to ensure you receive your product in a timely manner across India.Q: Where can these cutters be applied most effectively?

A: Deep Shoulder Milling Cutters are ideal for use in manufacturing settings, engineering workshops, and metalworking industries where precise slotting, shoulder milling, and surface finishing are critical tasks.Q: What is the process for operating this manual milling cutter?

A: The cutter is attached to a compatible milling machine and is manually controlled, allowing the operator to achieve precise depths, angles, and finishes during milling operations.Q: What are the main benefits of the polished coating on this cutter?

A: The polished coating enhances chip flow, reduces tool friction, and increases resistance to corrosion and premature wear, thereby extending the service life of the tool.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Indexable Tools Category

Rough & Finish Boring Bar For VMC

Price 6000.0 INR / Pack

Minimum Order Quantity : 10 Packs

Hardness : Hard

Coating : Polished

Material : Tungsten Carbide

Size : Various Sizes Available

Modular Indexable Boring Bar

Price 5000.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Hardness : Hard

Coating : Polished

Material : Tungsten Carbide

Size : Various Sizes Available

90 Degree Face Milling Cutter

Price 2500.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Hardness : Hard

Coating : Polished

Material : Tungsten Carbide

Size : Various Sizes Available

Indexable U Drills

Price 3400.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Hardness : Hard

Coating : Polished

Material : Tungsten Carbide

Size : Various Sizes Available

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese